Foam moulding car body parts

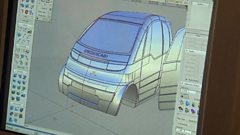

John Jostins, designer of the Microcab, explains some of the materials used to mould the prototype of the eco-friendly car.

First, the design team use a CAD machine to produce foam moulds of the car鈥檚 body parts. Softer foams are easier to work with, but denser and harder foams produce a more durable prototype. The machined foam pieces are then sanded, sprayed and finished, before being used as a mould for the car鈥檚 composite body parts.

Duration:

This clip is from

More clips from Science

-

![]()

Quality control of bottled drinks

Duration: 02:14

-

![]()

Marketing soft drinks

Duration: 01:31

-

![]()

Recording sound - analogue vs digital

Duration: 03:49

-

![]()

Computer-aided modelling of Microcab

Duration: 02:30

More clips from iD&T

-

![]()

Quality control of bottled drinks—Science

Duration: 02:14

-

![]()

Marketing soft drinks—Science

Duration: 01:31

-

![]()

Recording sound - analogue vs digital—Science

Duration: 03:49

-

![]()

Computer-aided modelling of Microcab—Science

Duration: 02:30