Cycle Road, Nottingham: Bicycles to Bombs

How a bike company evolved during the war; building a prosperous business

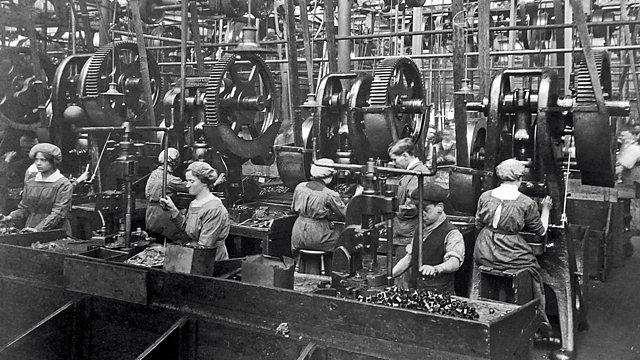

During the Great War, Raleigh sales received a huge boost. Whilst bicycle manufacturing continued, much of the factory was given over to munitions.

The government bought £24m worth of bespoke new war models for use by the troops. The bikes were khaki coloured and featured a gun prop.

The machinery for making Sturmey-Archer gears and engineering for bicycle tubing proved ideally suited for precision-making of fuses. The presses used for sheet steel parts were converted to the manufacture of Lewis gun magazines.

Raleigh pioneered the manufacture of a new kind of fuse. The direct-action 106-percussion-fuses acted on a lighter touch and were, therefore, more effective – or deadly – in the mud of the trenches.

By the end of the conflict the Raleigh factory had been transformed and the company had made millions.

The total sale of munitions to the government was £137m (in today’s equivalent). Frank Bowden and his son paid themselves over £9m in dividend payments between 1914-1918 (in today’s equivalent).

By 1918 Raleigh employed a workforce of nearly 5,000. The factory had been considerably expanded and equipped with a vast amount of new and sophisticated machinery, which led into a heyday of bicycle manufacturing in the subsequent decades.

Location: Cycle Road Nottingham NG7 2DT

Image: Workers at the Raleigh factory

Duration:

This clip is from

Featured in...

![]()

Latest stories from across the UK—World War One At Home

A selection of stories from At Home's November release.

![]()

�鶹������ҳ��� Radio Nottingham—World War One At Home

Places around Nottingham that tell a story of World War One

![]()

Home Front Life—World War One At Home

Everyday life in the towns, villages and countryside

More clips from World War One At Home

-

![]()

The loss of HMY Iolaire

Duration: 18:52

-

![]()

Scotland, Slamannan and the Argylls

Duration: 07:55

-

![]()

Scotland Museum of Edinburgh mourning dress

Duration: 06:17

-

![]()

Scotland Montrose 'GI Brides'

Duration: 06:41